Releasing boards

March 17, 2014The next few weeks are free of paying work (I do hope it is only the next few weeks but I am really glad to have a few weeks off).

I’m finally getting back to my own projects. The are-you-ok widget is probably the big one but before I get back to there, I’m releasing boards for my own project. Oh, some back story first:

I want a little motor board.

Actually, stepping further back… I want to build a tshirt that will help with my posture while sitting at a computer. The prototype is a T across the back, ending on each shoulder. There are three points along the top and three down the middle (with one share so there are five points). Each point has an accelerometer and a motor and connectors.

I want to pass PWR, GND, SDA, SCL to all five sensors somewhat using the motor boards as a way to conduct and split the signal. Also on the motor board is, well, a motor: a small coin cell sized motor.

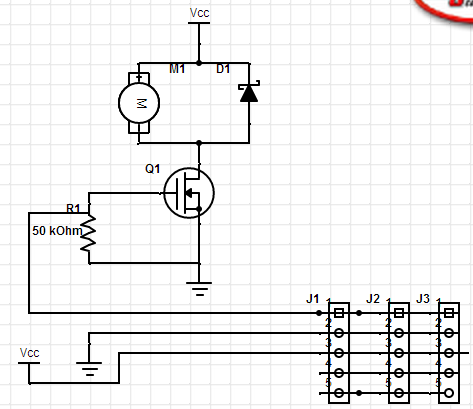

I want to turn the motor on via GPIO which doesn’t have enough current to direct drive the motor so I need a MOSFET. [Processors can’t drive motors directly because they don’t have enough oomph. The processor connects to the MOSFET which acts like a switch. Then the processor says “on”, the MOSFET turns the motor on, sourcing the power from another line (the voltage from the battery).]

Here is the schematic, using Digikey’s SchemeIt. Unfortunately, SchemeIt is not something I can use to send to a board (PCB) fabrication house. [That would be like drawing the outside of a house in detail but leaving the inside as an exercise to the builder.]

I have three connectors on the schematic, if the board is square, then these are on the East, West, and South sides. You can see the connection pass through to each connector.

I’ve wanted these boards for a long time, ever since I tried to make this (pretty simple) circuit myself. I’m not a good technician. I don’t have great soldering skills. What is worse, if it doesn’t involve a processor, I’m not very good at debugging hardware. So that was a swing and a miss.

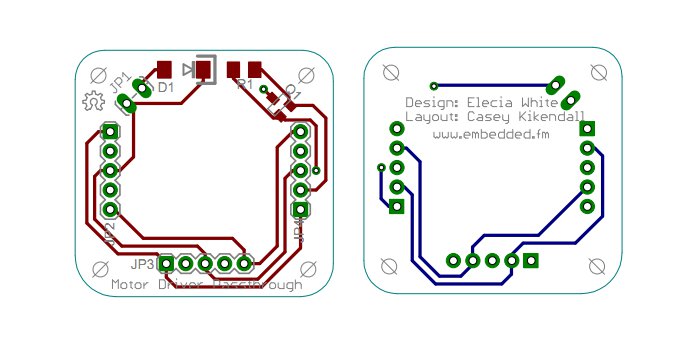

However, I have this podcast so I whined about it on the podcast. Well, actually, I wanted to know which electrical CAD software I should try (one that isn’t many thousands per seat). The answer is KiCAD but a listener said he could layout the board for me. And Casey did.

He finished in early December. And here we are in mid March. I am so embarrassed by the delay. One thing just led to another: new and difficult contract, the holidays, vacation, cold, working hard to make up for missed time, the embedded system conference deadlines. And with many such projects, once I got a couple weeks behind, instead of rising to the top, it just got buried.

However, getting buried is no excuse. I’m returning to dust it off and finish it. Having worked now with higher power motors (and with FETs and how to blow them up), I’m a little more confident in my circuit.

Now it is time for a few of the difficult parts. I have released boards to fab and kitted parts but that was a long time ago. I’m really nervous but I don’t have a good reason for it. This isn’t going to cost thousands of dollars, it is pretty cheap overall. I suspect the nerves are from it being a new thing and I’m doing it more in public so failure casts a wider shadow. I suppose “suck it up” is the only right answer to those feelings.

Things to do:

- Put it on github. This is an open source project, always was intended to be.

- Go to OSHPark to get boards fabricated, release the design files to them (the gerbers).

- Order parts from Digikey.

My goal is to get those done today. Then I’ll wait a couple weeks and put it all together. I’d better get to work.

This was a neat thing for me to put some time into. I look forward to seeing how it turns out.

Also, you will inevitably want to make some design changes at some point. This is the crappy thing about hardware; you can’t just hit ‘compile’ and play around with a new revision like you can in software. If these boards don’t work for you right off the bat, then do whatever it takes to get them working. Come Rev B you will have everything ironed out and ready for prime-time.