I’ve hinted about my personal project… I’m still not going to be specific about it but I will say that there are six pieces connected together via cables, fairly complicated cables.

I’ve been working with my single prototype, built by ordering parts from Sparkfun and laboriously put together, particularly given my soldering skills. It isn’t that I can’t solder, just that I don’t do it often so I tend to over-engineer my connections making each built circuit look like a tiny tank. Of solder.

Anyway, I need to move from one prototype for me to develop the idea to several prototypes to test the unit with actual users. I’d like to go to ten prototypes because that is what I’d ask for the firmware team if I was at a real company. You know, one with funding. Let’s just say the ten prototypes will be expensive and talk about funding another time.

What I want to discuss today is about connectors. By the title, you may already have clued in my feelings on said topic. But there is so much more to it than that. The only way to express the horror is to describe the whole process.

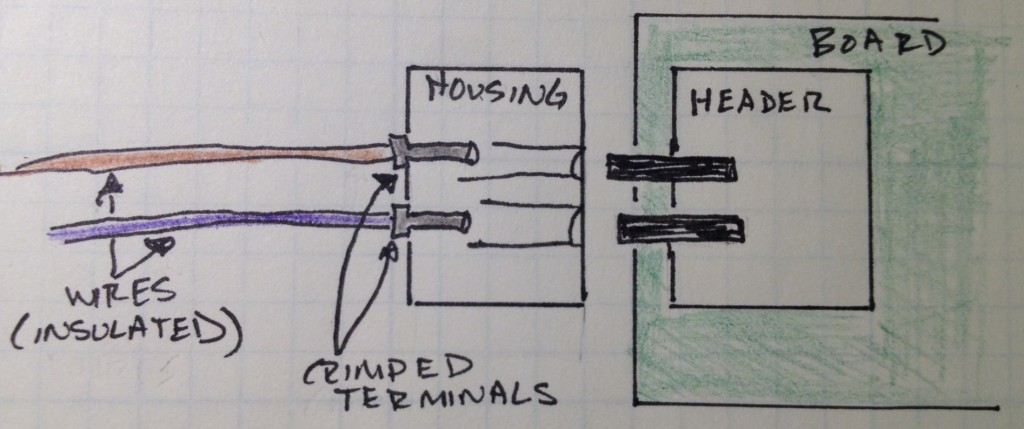

I started out with the number of wires I need to go to each piece of my system (five). For my prototype, I went to an electronics store and looked around for things about the right size. The resident helper-gnome sold me a wire crimper… Like some sort of medieval torture device a crimper puts a metal sleeve (terminal) on a wire so I can put it into the connector housing I’d chosen. Then I could attach my housing to the pins jutting out of the connector header on the board.

Got that? The housing is on the cable, the wires go in to it via crimped terminals. The board has a header that connects to the cables housing.

Crimping the wires requires a special tool. The usual cost for such a tool is between $400 and $2000 dollars. My head reels at what a scam that is.

The gnome helped me choose a $40 crimper tool that will work on most connectors of a certain size (0.1″ if you must know) and a certain wire gauge. Of course, I have to do three times more work than the expensive version but I’ve this is a labor of love. Right?

So I learned made cables with all this and it was difficult. By the end, I was near blind and my hands hurt. Right now, I need to make a couple cables longer (which means remaking them entirely). I’ve been putting it off for two weeks.

The pain of that is nothing compared the pain of trying to choose the correct connector for going forward.

I know I want a smaller connector for the small build than the prototype. And I need a lot of interconnects so cheap headers would be nice. I plan to have someone else make these cables but I need to be able to build extras or repair broken ones, so the tools can’t be horrendously expensive. Someday, when we build in the thousands, I might be able to get rid of connectors altogether actually soldering wires on to boards with some (unknown and magical) strain relief.

So, if you go to Digikey and search for connectors, you get a giant list of inexplicable things. There is no quick parametric search yet where I can enter the number of wires and the spacing. Like looking up the spelling of a word in the dictionary, you really have to know what you want before you get there.

I went for Board to Board – Arrays, Edge Type, Mezzanine. It had lots of options. And I got completely lost in the options. An EE friend came over to let me watch over his shoulder as he found some connectors for me. We ended up with a housing that is half the size of my current one, has keying (can’t plug it in backwards) . At the bottom of that page, you can see it links to mating products. Sorting out which of those would meet my needs meant reading about each one, trying to figure out what it meant. The datasheet didn’t exactly have a choose-your-own-adventure guide to connectors, more a terse listing of numbers and part drawings that looked like they were drawn by Escher.

We chose a header and selected terminals to crimp on to the wires. A complete set. And the EE thought that it would all work with my $40 crimper, though it might a little fussy.

In a different adventure, another EE came over and looked at all this. He said it was all wrong. Well, not all wrong. Just not right. Sure, it did all match which was good (better than my first on-my-own attempt). But my crimper wasn’t going to work… not really. I’d go blind first.

He suggested a different style of connectors (IDC) which don’t require terminals. (I didn’t think that was an option because I need discrete wires and not a ribbon but that is a detail, and they do make discrete wire IDC, it is just harder to find. As though I needed that.)

However, that connector variety still requires expensive crimpers. Though they don’t properly crimp so much as push things into the right place. The one we found online was only $80 on ebay but since its retail was $11,000 (boggle!), I wonder. Also, after 30 minutes of us both digging into the specs of the tool and the specs of the connectors he’d identified and assorted random standards, we determined it wouldn’t work for the connectors he’d chosen. Or any in the right size range.

The goal now is to haunt ebay and craigslist to find a second-hand crimper of the right size and then select connectors that work with that crimper. If anybody has a matrix of which crimpers work with which connectors, do let me know? Until then, I’ll be going cross-eyed trying to figure it out.